Engineering

Engineering is the core of what we do, from early front-end conceptual work through definition engineering in support of equipment / package procurement or project development. We target to develop the right engineering solution through the front-end process to help maximise value. Our engineering is focused across the core areas of pipelines, structures and controls in support of subsea assets. The engineering solutions account for the drive to reduce waste and achieve net zero.

Case Studies

SUBSEA ENGINEERING – SINGLE VESSEL SOLUTION

SAMPHIRE SUBSEA CASE STUDY

Challenge

Gas service and two production risers were at the end of their design life and required to be replaced to ensure the facilities could be supported until end of field life. Selection of the subsea engineering solution for the riser replacement works was critical and would largely dictate project costs.

The work required shallow diving under the FPSO turret, winch operations for product recovery / installation and sat diving for the subsea connection to the riser base.

Solution

Traditional selection criteria would dictate a two vessel solution; DSV for install and sat works and a support vessel for the air diving operations.

Samphire completed a technical evaluation of the work at the subsea contractor selection stage to consider if a DSV with a larger deck could accommodate all equipment to provide a one vessel solution. This resulted in the selection of a mid-size DSV as the installation vessel.

Further efficiencies and optimisations were made following review of deck layouts, equipment footprints, installation schedules and vessel operations.

Result

As a result three gas service and two production risers were replaced over two campaigns with one vessel creating an overall safer solution and delivering significant cost savings for the client.

SUBSEA ENGINEERING – PROJECT REVIEW

SAMPHIRE SUBSEA CASE STUDY

Challenge

The operator of a subsea field was progressing with the engineering associated with tying a new field back to an existing host.

Samphire was engaged by an investment partner to review the project Select phase technical documentation. This involved reviewing a number of technical documents, reports and drawings while ensuring that relevant technical and operational considerations were also adequately covered in the TPOSA and CTIA commercial agreements under development.

The objective of the work was to ensure that the hosts commercial interest in the area was considered and adequately protected.

The review included consideration of the proposed subsea tie-in arrangement, modifications required, material selection, shutdown requirements, operability considerations and potential back-out of existing fields’ production.

The proposed Host platform modifications were also reviewed to ensure that shutdown requirements and the overall impact to existing production and operations were understood.

Solution

Samphire provided the process, subsea and material technical resources needed to co-ordinate and undertake the technical review while interfacing with the technical and commercial teams of the third party operator.

Result

The review enabled the partner to have confidence in the solution to support the investment decision.

SUBSEA ENGINEERING – DEBOTTLENECKING STUDY

SAMPHIRE SUBSEA CASE STUDY

Challenge

The client had committed to new drilling in an existing mature area, the additional volumes expected from the development work required the subsea system to be debottlenecked.

Solution

Samphire was engaged to complete the debottlenecking study design across the subsea and topsides infrastructure.

Various options were identified, these were developed technically to adequate detail to allow evaluation across risk, cost and schedule.

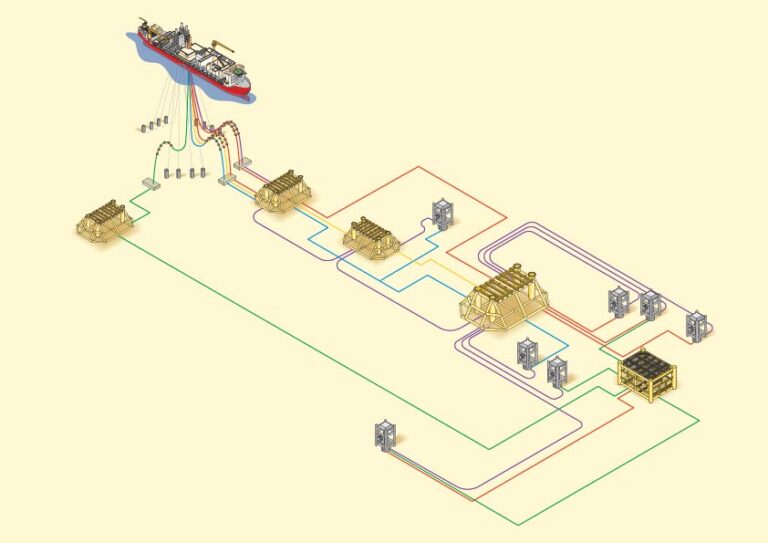

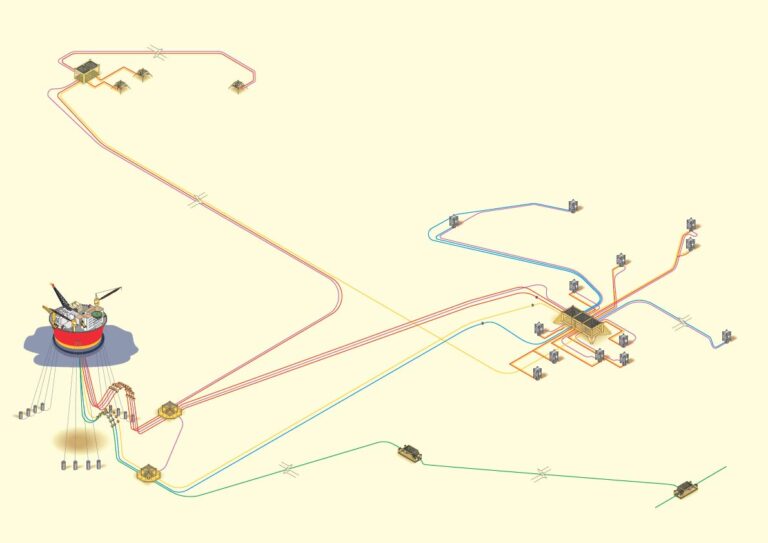

The scope covered a new pipeline system, new structures, new riser system, control system modifications along with topsides modifications to support the subsea works on the FPSO.

The work compromised risk reviews, design basis development, cost basis, study report along with all layout / design drawings.

Result

The output from the study enabled the client to progress with the new development work and select a basis for the debottlenecking of the subsea architecture.

SUBSEA ENGINEERING – pRE FEED STUDY WORK

SAMPHIRE SUBSEA CASE STUDY

Challenge

Samphire has been engaged in various pre FEED study works to support the technical scope definition through the initial work development phase. The work covers topsides and subsea facilities with Samphire acting for the operator on behalf of the host facilities.

Solution

Samphire has defined the subsea architecture in terms of subsea works or managed third party contractors for topsides work. The work involves close engagement with commercial to understand the economics and the risks.

Samphire have applied their execute end skills to the front end works to deliver practical and pragmatic solutions where the capex spend is minimised for these marginal developments. A good understanding of risk ensures that technical or commercial solutions can be applied to develop a robust basis for the early stage.

Samphire brings the execution knowledge into the project costings and schedules to ensure the basis is deliverable.

Result

A robust solution for the new developments was framed to enable the economics to be completed on a robust basis for decision making.

SUBSEA ENGINEERING – SUBSEA FEED

SAMPHIRE SUBSEA CASE STUDY

Challenge

Samphire has developed various subsea fields for third party tie backs across the North Sea. This includes close engagement with the operator to understand the key development risks, flow assurance issues and production chemistry challenges to ensure an effective overall solution.

The FEED work covered all key areas; well site configuration / layout, manifold design, pipeline design across production and gas lift as well as tie in structure development. Samphire completed design reviews with the operator and our experienced operations / execution resources to ensure both deliverability and usability of the design.

Where possible Samphire developed the design on a standard basis to assist future works ie: standard specifications, etc.

Solution

On the back of the FEED work, Samphire developed the installation scope of work and validated all tenders to support contractor selection.

Result

The work has since been installed offshore with very little change from the FEED work, supporting the quality of the design.

WORK SCREENING / EVALUATION

SAMPHIRE SUBSEA CASE STUDY

Challenge

In any business environment, proper screening and evaluation of asset changes is critical. This ensures only the most significant business, operational, environmental or safety modifications are progressed. To optimise business costs, all low value work is screened out.

The Samphire team has experience across a number of engineering modification systems which helps ensure good practice is applied through the modification process.

Solution

More specifically, Samphire has worked with a mid-tier operator, evaluating their engineering change process to ensure it accommodated all key business areas, it was being appropriately applied with the right people engaged in it. The work involved a review of recent asset changes to ensure these were properly documented; an assessment of each change was made against the process including asset documentation validation against the change (for completed works). Any work that was not progressed had a clear quantified risk associated with it for future review.

Result

Newly identified work was screened through the process and this resulted in the low value work being screened out. This positively impacted the current and future budgets.